The three major trends of ball valves: intelligence, sustainability, and customization.

2025-07-16

Shanghai, China - With the acceleration of global industrial automation and increasingly strict environmental regulations, the ½-inch ball valve market is undergoing unprecedented technological innovations. As a key component in the field of fluid control, the ½-inch ball valve is rapidly evolving towards intelligence, environmental friendliness, and customization, providing users in various industries with more efficient and sustainable solutions.

Innovative materials drive performance breakthroughs

The latest advancements in materials science are significantly enhancing the performance of ½-inch ball valves. Leading companies in the industry are adopting them:

Special alloy materials: such as super duplex stainless steel, nickel-based alloys, etc.

Advanced surface treatment technologies: including plasma spraying, nano-coating, etc.

High-performance sealing materials: such as reinforced PTFE and graphite composite materials

These innovations have enabled the ball valve to extend its service life by more than 40% under harsh conditions such as extreme temperatures, high pressure, and corrosive media.

The intelligent transformation is unstoppable.

The deep integration of Internet of Things technology and the ½-inch ball valve is reshaping the industry landscape:Remote monitoring system: Real-time monitoring of valve status and fluid parameters;Predictive Maintenance: Using AI algorithms to proactively alert of potential failures;Automation control: Seamless integration with the industrial Internet of Things platform.

Green solutions are highly favored.

Driven by the carbon neutrality goal, the demand for environmentally friendly ½-inch ball valves has soared:Compliant with the latest ISO 15848-1 low leakage standard;Energy-saving design reduces system energy consumption by 15-20%;Use recyclable materials and environmentally friendly production processes.

Customized services meet diverse needs

To adapt to different application scenarios, ½-inch ball valves are showing a diversified trend:Compact design: Suitable for installation environments with limited space;Multifunctional integration: such as composite valves with filtering and regulating functions;Quick Customization Service: 3D Printing Technology Enables 72-Hour Rapid Delivery.

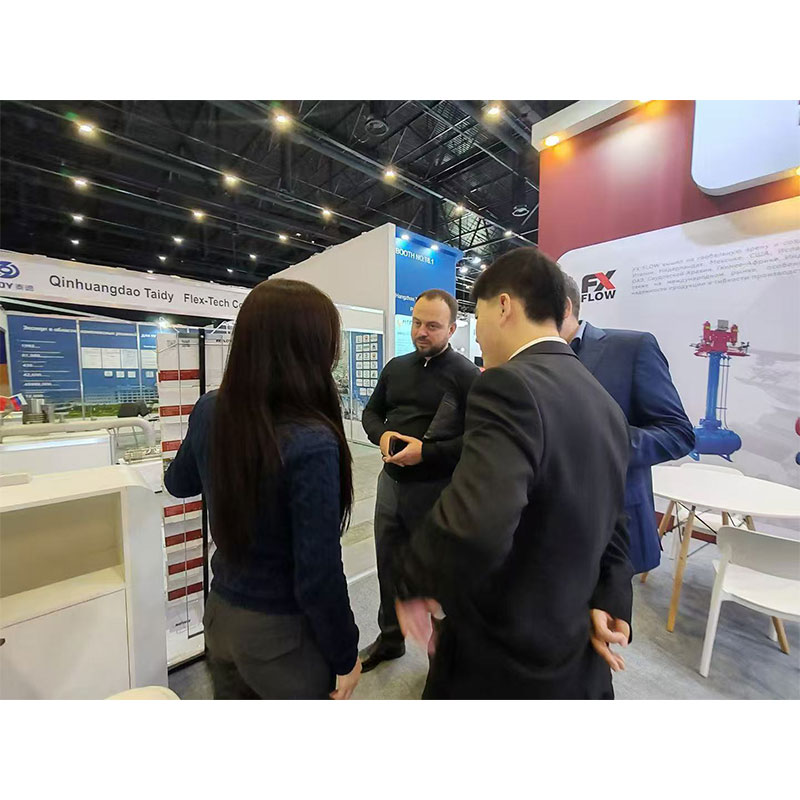

FX Flow Control BV is a world-leading supplier of fluid control solutions, with extensive industry experience. Its products are exported to over 40 countries and regions. We are always committed to creating value for our customers through technological innovation.